10 Mar 2024

Are you interested in learning how to manufacture surimi? Surimi is a popular seafood product that can be used as a secret treat.

The surimi manufacturing process involves several steps to ensure its quality and safety. From filleting to packaging and preserving, you will find everything on how to manufacture surimi. Let’s dive in!

Surimi Manufacturing Process

How to manufacture surimi is not just a short phase of learning. You should set aside some time to truly understand each step required in the surimi manufacturing process.

This is the perfect start for you!

Filleting

Filleting is essential for the surimi manufacturing process. Following the fish selection step, filleting prepares all of those selected fish for deboning.

During the filleting process, water nozzles cleanse the fish and remove any undesired parts. These water nozzles also cleanse and eliminate toxins from fish.

In addition to water nozzles, a plastic bristle wheel brush can also help remove unwanted parts from fillets. Scrubbing the fish with this brush removes any remaining dirt.

The water nozzles and plastic bristle wheel brush ensure that the surimi production process produces just the right fish fillets. These fillets are ready for the next step in the surimi manufacturing process.

Fun fact: Equipment for filleting and mincing surimi is specifically designed for round fish such as Alaska pollock and Pacific whiting.

Deboning (Mincing)

In surimi manufacturing, processors commonly use a roller-type meat separation process to mince and debone fish. This process involves pressing different fish cuts against a rubber belt and a steel drum with 3–5 mm holes.

Then this process will sort the meat from the skin, bones, cartilage, and other unwanted parts.

For at-sea processing, 3–4 mm orifices provide the optimum quality and yield retention. Shore-side plants may use 5-mm drums. A mechanical deboner with an opening greater than 5 mm generates larger meat particles but makes contamination removal difficult.

Washing and Dewatering

The next important steps of the surimi manufacturing process are washing and dewatering. More water-soluble proteins and contaminants improve surimi gel formation and quality.

This process concentrates myofibrillar proteins by reducing water-soluble proteins, which positively improves surimi's functional properties.

Proper washing is essential for making high-quality surimi, since improper washing might reduce gel quality. However, over-washing can increase meat moisture and make refining and dewatering harder.

The process requires attention to water temperature, fish age, and processing technique. All those factors affected washing efficiency.

Refining

In surimi manufacturing, the refining process removes impurities like skin, bones, and connective tissues from washed mince before dewatering.

Refiners must remove contaminants in this process, with screen sizes and speeds determining surimi cleanliness and recovery rate.

Proper adjustment of the refining process is essential for optimal moisture content, which ensures effective impurity removal without compromising product quality.

Screw Press

The screw press in surimi production reduces moisture, which increases during washing and refining. The moisture content needs to be reduced to 80–84% before blending with cryoprotectants and freezing.

The effectiveness of water removal depends on the screw press. A longer screw and a larger volume reduction ratio make dehydration work better.

The surimi manufacturing process uses screens with 0.5 to 1.5 mm holes to achieve 82% moisture from a 2:1 screw press compression ratio.

Salt in the washing tank speeds water removal but reduces frozen food shelf life; thus, it requires proper regulation.

Packaging & Preserving

Packaging and preservation also play a crucial role in enhancing product appearance and extending shelf life. In this process, considering technical and marketing aspects is important.

This process aims to maintain the freshness of surimi by creating a protective barrier against oxygen, light, and moisture. Reduced exposure to these elements can extend surimi's shelf life, keeping it fresher.

Other than that, surimi packaging should be transportable and stylish with designs and labeling. In the surimi industry, common packaging materials include polyester, polypropylene, polyvinylidene chloride, ethylene vinyl alcohol, polyethylene, and adhesive, which each offer specific properties.

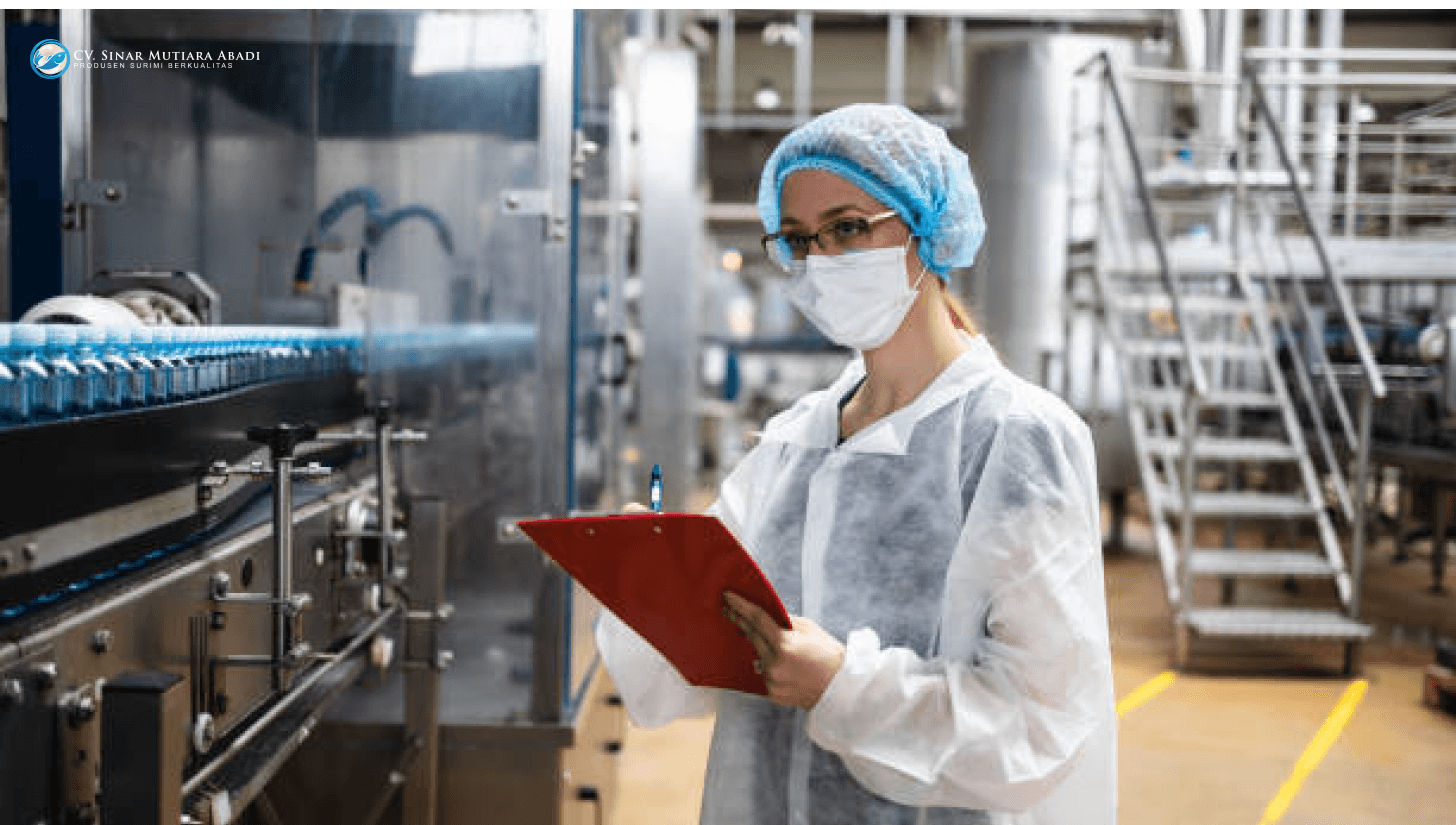

Hygiene and Safety Protocol

Insects

Certain components used in surimi manufacturing may cause significant allergies. This process involves using cochineal insects to obtain carmine.

Manufacturers must clearly label surimi products if they contain insect-derived materials. Labeling things correctly will make people more aware of what is in them. This helps maintain the hygiene and safety of the final product.

Metal Detector

The biggest risk in the surimi manufacturing process is the potential mixing of metal pieces. Most of the time, ferrous, copper, aluminum, lead, and stainless steel are the most common kinds of contamination.

Therefore, processors must pass the surimi through a metal detector before packing to ensure it is clean and safe.

Real Raw Material

In some countries, in order to fulfill the food laws and regulations, both cold water and tropical surimi products must prove their raw materials. In Indonesia, authorities inquired about the raw materials used to make surimi-based products.

For safety reasons, surimi labeling must demonstrate the realness and quality of the raw materials used in production.

Trends and Technology

Processors have used several important trends and technological advances in the surimi manufacturing process.

Finding the best techniques to break down actin, a protein in fish muscle that gives surimi its shape and gel-forming property, is a surimi industry trend.

Moreover, some countries, especially the US and Japan, use vacuum-cutting technology that uses suction pressure for precision and speed.

Another new trend in surimi production is the use of leached fish meat, which enhances efficiency, quality, and cost. In Malaysia and southern Thailand, processors mostly use this trend.

The development of technology is clearly taking a major part in the process of making high-quality surimi.

Conclusion

All in all, learning how to manufacture surimi is not a short phase of learning. The surimi manufacturing process includes filleting, deboning, washing, and packaging to assure quality and safety.

Technological advancements have been undeniably enhancing surimi production. Overall, the surimi manufacturing process is not about production. Rather, it is a blend of journey and innovation, aiming to produce high-quality surimi for consumers worldwide.

Alamat: Gajah Mada KM 4, Banyudono, Kaliori, Rembang 59252

Nomor Telepon: +62 822 98989 169

Email: marketing@sinarmutiaraabadi.co